Innovation and Quality in

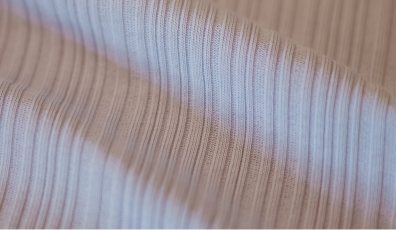

Textile Fabrics

.

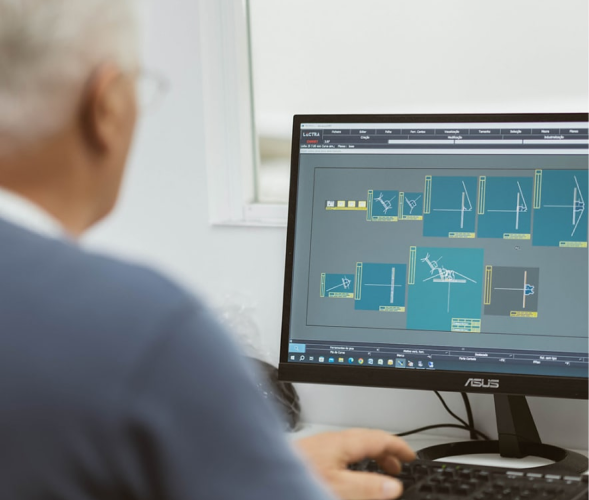

Welcome to Vipaltex, where innovation and quality meet in our textile fabrics. We are proud to be involved in the entire process of creating your collections, from conception to production.

Since 1985

Knitting and Manufacturing .

Founded in 1985 by Vitorino Cruz, VIPALTEX has grown from a small family textile business to a prominent position in the national textile industry, centrally located in a region closely associated with textile industry.

Driven by decades of experience and founded on a strong family base with future generations to come, VIPALTEX has 2 distinct centers in operation:

- Knitting: one center entirely dedicated to Knitting all types of fabrics and compositions

- Manufacturing: one center dedicated to creating and manufacturing men's, women's, children's and babies' garments.

The creation of two distinct centers has earned the company a renowned place among the best textile companies in the region, establishing a symbiosis of success.

We are proud to say that we guide ourselves by the principles of accuracy, ethics and humanism, bearing in mind the vision of constant evolution in order to meet the expectations of excellence of those who come to us.

Knitting - Barcelos Unit .

Knitting Portfolio